Key Highlights:

- Manufacturing analytics brings clarity to demand forecasting in manufacturing by connecting sales, production, and supply chain data into one reliable view.

- Manufacturing data analytics in demand forecasting helps reduce uncertainty, enabling better production planning, analytics, and more balanced inventory decisions.

- Predictive analytics in the manufacturing industry shifts forecasting from reactive to proactive, allowing teams to anticipate demand changes earlier.

Introduction

You know that uneasy feeling manufacturers get when last month’s best-seller suddenly stops moving or when a product no one expected takes off overnight? That gap between what you produced and what the market actually wanted is where most demand problems begin.

Picture this: A manufacturer produces 50,000 units, confident they’ll sell fast. Three months later, 30,000 are gathering dust in a warehouse. Meanwhile, their competitor sold out in weeks because they somehow knew exactly what the market wanted.

What made the difference? Manufacturing analytics.

Instead of asking, What did we sell last year?, Manufacturers can now ask smarter questions, like,

- What signals are customers giving us right now?

- What do current market trends look like?

- How will seasonality, promotions, or supply disruptions impact demand next quarter?

By using data analytics in manufacturing, businesses can connect sales data, production capacity, inventory levels, and supply chain inputs into one clear picture. When you combine real-time production data with historical sales patterns and market trends, something magical happens. Suddenly, you’re not just forecasting, you’re predicting with precision.

Companies using AI-driven demand forecasting can reduce forecasting errors by 20% to 50% and cut product unavailability by up to 65% compared with traditional forecasting methods.

What Is Manufacturing Analytics?

Manufacturing analytics is the process of collecting and examining data generated throughout a factory, like information from machines, inventory systems, sensors, and production reports, to turn it into insights that help manufacturers make smarter decisions.

Instead of guessing how much to produce, when to schedule maintenance, or how to manage inventory, analytics paints a complete picture of operations.

Manufacturing analytics is the discipline of converting manufacturing data into actionable insights, aggregating and analyzing data from machines, systems, workers and supply chain data analytics to optimize operations, improve productivity, and enable faster, smarter decision-making.

Manufacturing analytics helps companies improve production efficiency, detect issues early, optimize inventory, and align manufacturing with actual market needs.

What Is Demand Forecasting in Manufacturing?

Demand forecasting in manufacturing is about predicting how much of a product customers will want in the future so manufacturers can plan production, inventory, and supply chain activities accordingly.

Instead of producing based on assumptions or last year’s numbers alone, manufacturers use data to estimate future demand more accurately. This helps them decide what to produce, how much to produce, and when to produce it without overstocking or running out of products.

In practical terms, demand forecasting in manufacturing connects sales trends, seasonality, market signals, and supply chain data to guide smarter decisions.

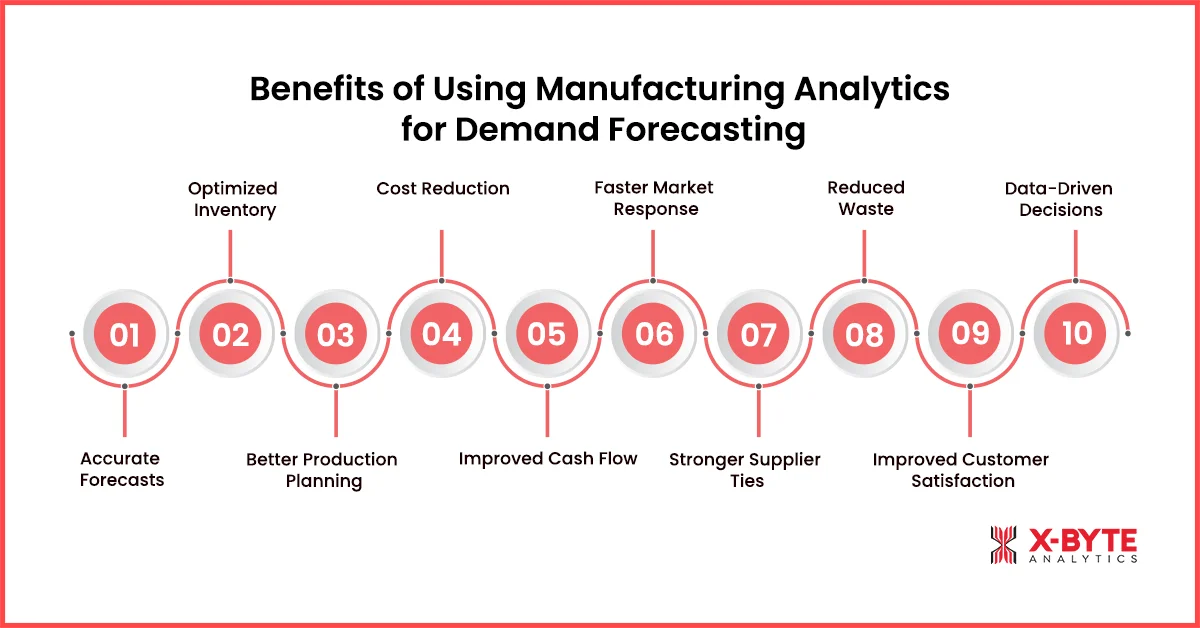

Benefits of Using Manufacturing Analytics for Demand Forecasting

By bringing together data analytics in manufacturing, production data, and supply chain inputs, Manufacturing data analytics in demand forecasting creates a stronger foundation for demand forecasting in manufacturing.

It sets the stage for more informed planning across Demand Forecasting in the Supply Chain, helping manufacturers move from reactive decisions to more structured, forward-looking approaches without overcomplicating the process.

1. Improved Forecast Accuracy

Manufacturing data analytics in demand forecasting dramatically reduces forecasting errors by analyzing historical patterns, seasonal trends, and market signals. Instead of relying on gut instinct, predictive analytics in the manufacturing industry uses algorithms to identify patterns humans might miss, leading to accuracy improvements of 20–50% for many manufacturers. These insights are often visualized through a manufacturing dashboard example that clearly highlights demand trends, forecast deviations, and planning gaps for decision-makers.

2. Optimized Inventory Management

Say goodbye to overstocking and stock-outs. Data analytics in manufacturing enables precise inventory optimization by predicting exactly what you’ll need and when. This means less capital tied up in excess inventory and fewer lost sales from running out of popular products. Supply chain demand forecasting becomes a strategic advantage rather than a constant headache.

PepsiCo used manufacturing analytics to save 10% in inventory costs!

At the scale PepsiCo operates, forecasting demand isn’t simple. Thousands of SKUs, multiple regions, seasonal spikes, and promotions make traditional forecasting models struggle to keep up.

By using predictive analytics and AI-driven demand planning, PepsiCo shifted from manual-heavy forecasting to smarter, more adaptive models.

What changed:

- Forecast accuracy improved by around 20%

- Inventory costs dropped by up to 10%

- Teams saved thousands of work hours by automating demand planning processes

The real win wasn’t just better forecasts; it was freeing teams from constant rework and last-minute fixes.

3. Enhanced Production Planning

Production planning analytics allows manufacturers to align their schedules with actual demand. You can adjust production runs, allocate resources efficiently, and prevent bottlenecks before they happen. This synchronization between forecasted demand and production capacity reduces waste and maximizes equipment utilization.

4. Reduced Costs Across the Board

When demand forecasting in the supply chain is accurate, the savings compound. Lower inventory carrying costs, reduced overtime expenses, minimized waste from overproduction, and fewer emergency shipments all contribute to healthier profit margins. Some manufacturers report cost reductions of 15-30% in their supply chain operations.

How did Danone, the global food and beverage manufacturer, achieved 30% reduction in lost sales with manufacturing analytics?

For a company like Danone, demand forecasting isn’t just about numbers; it directly affects waste, shelf life, and lost revenue. With perishable products, even small forecasting errors can mean throwing away stock or missing customer demand.

Danone adopted machine-learning-based demand forecasting to better understand what customers would actually buy, not what last year’s spreadsheet suggested.

What changed:

- Forecast errors dropped by 20%, making planning far more reliable

- Lost sales reduced by 30% because products were available when needed

- Product waste fell by 30%, easing both financial and sustainability pressure

5. Better Cash Flow Management

Accurate forecasting means you’re not tying up cash in excess raw materials or finished goods. Manufacturing analytics in demand forecasting helps you predict capital requirements more precisely, allowing for smarter financial planning and improved working capital efficiency.

6. Faster Response to Market Changes

Predictive analytics in supply chain management provides real-time insights that help you pivot quickly. When demand shifts, whether from seasonal changes, competitor actions, or market trends, you can adjust production proactively rather than reactively.

7. Stronger Supplier Relationships

When you can provide suppliers with accurate forecasts powered by manufacturing analytics, they can better plan their own production. This creates a more reliable demand forecasting in the supply chain ecosystem, leading to better pricing, improved delivery times, and stronger partnerships.

How Fordis Using Manufacturing Analytics for Demand Forecasting & Managing Global Supply Chain?

For Ford, demand forecasting affects everything, from supplier coordination to factory scheduling across continents. Any mismatch between demand and production can ripple across the entire supply chain. Ford applied predictive analytics to better anticipate demand changes and align production planning with real market needs.

What changed:

- Inventory costs reduced by up to 30%

- Delivery times improved by up to 75%

- Supply chain planning became more proactive, not reactive

This shows how demand forecasting in manufacturing isn’t just about forecasting sales, it’s about protecting the entire ecosystem.

8. Reduced Waste and Sustainability

Overproduction isn’t just expensive, it’s wasteful. AI-driven demand forecasting helps manufacturers produce what’s actually needed, reducing material waste, energy consumption, and environmental impact. It’s better for the planet and your bottom line.

9. Improved Customer Satisfaction

Having the right products available when customers want them is the ultimate competitive advantage. Sales forecasting models powered by analytics ensure you meet customer demand consistently, building loyalty and reducing lost sales opportunities.

10. Data-Driven Decision Making

Perhaps the biggest benefit? Predictive analytics in the supply chain replaces guesswork with evidence. Every decision, from production schedules to purchasing orders, is backed by data, trends, and statistical models, giving leadership confidence in their strategic choices.

Improve Demand Forecasting In Manufacturing With Analytics-Driven Insights That Optimize Production, Inventory, And Supply Planning.

How Manufacturing Analytics Supports SMEs vs Large Manufacturers?

Manufacturing analytics plays a different, but equally important, role for small and mid-sized manufacturers (SMEs) compared to large enterprises. While both rely on manufacturing analytics and data analytics in manufacturing to improve efficiency and forecasting, the way they use these insights often reflects their scale, resources, and operational complexity.

Let’s find out better:

| Aspect | SMEs (Small & Mid-Sized Manufacturers) | Large Manufacturers |

| Primary Goal | Improve visibility, reduce waste, and stabilize operations | Optimize scale, efficiency, and global coordination |

| Use of Manufacturing Analytics | Focuses on basic insights from sales, inventory, and production data | Combines data from multiple plants, regions, and systems |

| Demand Forecasting in Manufacturing | Short-term forecasting to prevent overproduction or stock-outs | Long-term, multi-region forecasting across product lines |

| Manufacturing Data Analytics in Demand Forecasting | Used to analyze historical sales, seasonal demand, and order trends | Used to model complex demand patterns across markets and channels |

| Predictive Analytics in the Manufacturing Industry | Supports simple forecasts and production planning analytics | Enables advanced AI-driven demand forecasting and scenario planning |

| Supply Chain Demand Forecasting | Focuses on supplier availability and local distribution | Balances global supply chains and demand signals in real time |

| Inventory Optimization | Keeps inventory lean due to limited storage and working capital | Optimizes inventory across warehouses and distribution centers |

| Sales Forecasting Models | Relies on straightforward models with fewer variables | Uses sophisticated models incorporating market, pricing, and macro data |

| Data Analytics in Manufacturing | Often uses affordable, easy-to-deploy tools | Integrates enterprise-level analytics platforms |

| Manufacturing in Demand Forecasting | Helps SMEs react faster to market changes | Helps large manufacturers plan proactively at scale |

Tools & Technologies Used in Predictive Analytics for Forecasting

By combining manufacturing analytics with modern tools and technologies, businesses can bring structure to demand forecasting in manufacturing and demand forecasting in the Supply Chain.

These tools & tech support analytics-driven demand forecasting by turning raw data into forward-looking insights, helping teams move from reactive planning to more confident, data-driven forecasting without adding unnecessary complexity.

| Tool / Technology | What It Does | How It Supports Demand Forecasting in Manufacturing |

| Machine Learning Forecasting Tools | Learn patterns from historical and real-time data | Improve forecast accuracy by adapting to changing demand trends and customer behavior |

| Time-Series Forecasting Tools | Analyze demand data over time (trends, seasonality) | Support short- and medium-term production planning analytics |

| Data Analytics & BI Platforms | Collect, clean, and visualize data from multiple systems | Create a reliable foundation for data-driven demand forecasting in manufacturing |

| AI-Driven Demand Forecasting Tools | Use AI models to predict future demand scenarios | Enable proactive planning and reduce reliance on manual sales forecasting models |

| Cloud-Based Analytics Platforms | Store and process large volumes of data at scale | Make predictive analytics in the manufacturing industry accessible and scalable |

| ERP & Supply Chain Systems | Centralize sales, inventory, and production data | Ensure consistency across Demand Forecasting in the Supply Chain |

| IoT & Sensor Data Platforms | Capture real-time production and inventory data | Improve forecast responsiveness using live operational signals |

| Predictive Analytics Platforms | Combine multiple models and data sources | Strengthen predictive analytics in supply chain management |

| Visualization & Dashboard Tools | Present forecasts in easy-to-understand formats | Help teams act quickly on forecasting insights |

| Scenario & What-If Analysis Tools | Simulate demand changes and disruptions | Support better decision-making during uncertainty and market volatility |

Best Practices for Implementing Manufacturing Analytics for Demand Forecasting

If there’s one thing experience teaches in demand forecasting, it’s this: analytics only works when it’s implemented with intention. Many manufacturers invest in tools but struggle to see results, not because the technology is wrong, but because the approach isn’t grounded in how manufacturing and supply chains actually operate.

Done right, manufacturing analytics becomes a practical decision-making layer that steadily improves forecast accuracy over time.

Here are some proven best practices that make demand forecasting in manufacturing truly effective.

1. Start With the Right Data, Not More Data

Before jumping into models or dashboards, focus on data quality. Clean, consistent sales data, production records, and inventory data matter far more than having massive datasets. Strong data analytics in manufacturing begins with reliable inputs; otherwise, even advanced AI-driven demand forecasting will produce misleading results.

2. Use Manufacturing Data Analytics in Demand Forecasting as a Continuous Process

Demand doesn’t stay still, and forecasts shouldn’t either. The most effective manufacturers update forecasts regularly using fresh sales data and supply chain signals. When Manufacturing data analytics in demand forecasting becomes a continuous process, not a monthly exercise, decisions stay timely and relevant.

3. Balance Predictive Models With Business Context

While predictive analytics in the manufacturing industry can identify patterns, human context still matters. Promotions, new product launches, regulatory changes, or market shifts often don’t show up in historical data. The best results come when analytics insights are combined with on-ground knowledge.

4. Start Simple, Then Scale

You don’t need complex models on day one. Many manufacturers see quick wins using basic forecasting methods and then gradually add predictive analytics in supply chain management as their data improves. Starting simple builds confidence and makes adoption easier across teams.

5. Align Inventory Optimization With Forecast Accuracy

Demand forecasting and inventory decisions should move together. Accurate forecasts enable smarter inventory optimization, reducing excess stock without increasing the risk of stockouts. This is especially critical in supply chain demand forecasting, where even small errors can ripple across suppliers and distributors.

6. Make Forecast Insights Easy to Act On

Forecasts should lead to decisions, not confusion. Clear visualizations, shared dashboards, and simple explanations help teams across sales, operations, and supply chain act confidently on insights. When these insights are delivered through a power bi manufacturing dashboard, decision-makers can instantly see demand shifts, inventory risks, and production constraints in one unified view. When analytics supports everyday decisions, manufacturing in demand forecasting becomes part of the workflow, not an isolated function.

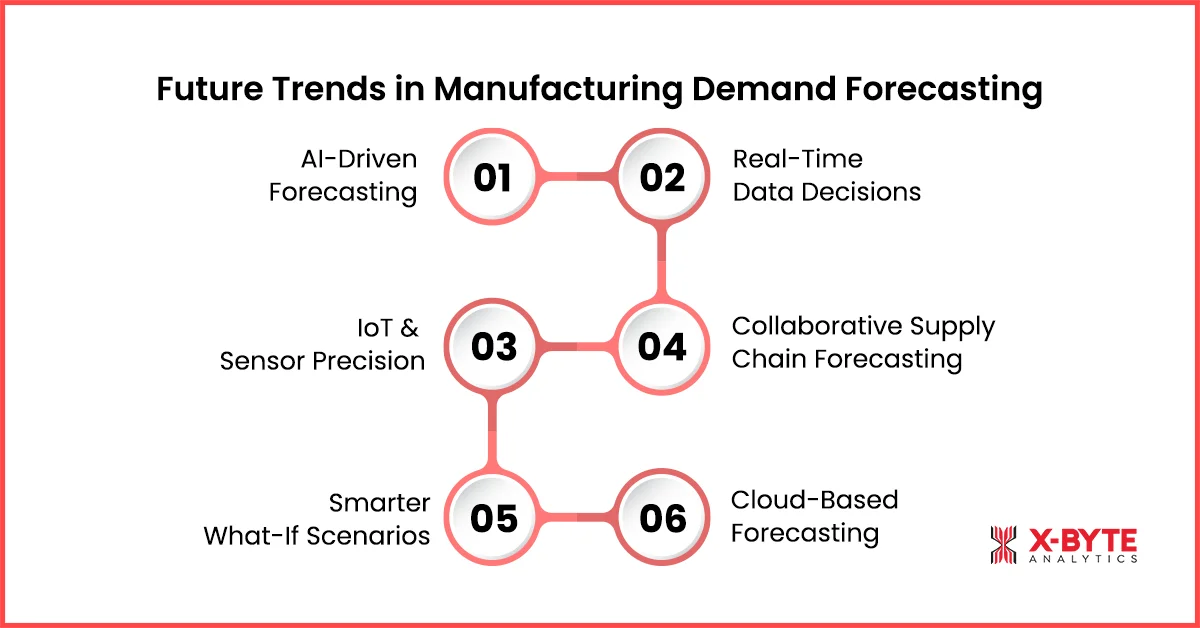

Future Trends in Manufacturing Demand Forecasting

The world of manufacturing is evolving fast, and so is the way companies forecast demand. As factories become smarter and data becomes more abundant, demand forecasting in manufacturing is shifting significantly. Here’s a look at the key trends shaping the future of this space-explained in a simple, conversational way.

1. AI-Driven Demand Forecasting Will Become Mainstream

Artificial intelligence isn’t just a buzzword. It’s reshaping how forecasts are made. Instead of relying solely on historical sales, manufacturers are increasingly adopting ai-driven demand forecasting models that pull in signals like market trends, customer sentiment, weather patterns, and promotional calendars. This means forecasts will become more accurate and more agile, especially when integrated into manufacturing analytics.

How it will benefit: Manufacturers will be able to predict sudden changes in demand before they happen, helping prevent stockouts and excess inventory.

2. Real-Time Data Will Drive Faster Decisions

Traditionally, demand forecasts were updated monthly or weekly. But with real-time data from production lines, sales systems, and suppliers, forecasts can adjust instantly. Predictive analytics in the supply chain will tap into live data streams so planners can react to disruptions as they unfold.

How it will benefit: If a key supplier suddenly delays delivery, your demand forecast and your production schedule can adapt right away instead of waiting for the next planning cycle.

3. IoT and Sensor Data Will Enhance Precision

The Internet of Things (IoT) is adding another layer of clarity to demand forecasting. Sensors on machines, warehouses, and transport fleets feed back detailed information about production rates, inventory levels, and equipment performance. When combined with predictive analytics in the manufacturing industry, these insights help improve forecast accuracy and operational efficiency.

How it benefits you: You’ll not only forecast what customers will buy, but also know how ready your plant is to deliver it.

4. Collaborative Forecasting Across the Supply Chain

In the future, forecasting won’t be confined to one department. Manufacturers, suppliers, distributors, and even retailers will share data and forecasting models for better alignment. This collaborative approach strengthens supply chain demand forecasting and reduces friction between partners.

How it helps: When everyone in the supply chain works from the same forecast, you’ll see fewer stockouts, fewer excess orders, and better coordination overall.

5. Smarter Scenario Planning With What-If Analytics

Forecasts used to tell you what’s likely to happen. Tomorrow’s tools will also show what could happen under different scenarios, like a sudden spike in demand, a supply disruption, or a pricing change. This kind of simulation, powered by predictive analytics in supply chain management, gives manufacturers more confidence to plan for uncertainty.

How it helps: Your team can explore alternate futures and pick strategies that work even when the unexpected occurs.

6. Cloud-Based Forecasting for Greater Accessibility

Cloud tools are making advanced forecasting easier and more scalable for all manufacturers, big or small. With cloud platforms, data is unified in one place, models are updated automatically, and insights are accessible from anywhere. This democratizes data analytics in manufacturing and speeds up decision cycles.

How it helps: Small and medium manufacturers can access the same forecasting power that was once limited to large enterprises.

Unlock Accurate Demand Forecasting In Manufacturing Using Predictive Analytics To Reduce Waste And Improve Operational Efficiency.

Conclusion

Demand forecasting in manufacturing works best when it’s grounded in real data, real constraints, and real business goals. With the right approach to manufacturing analytics, forecasting stops being a guessing exercise and becomes a reliable input for production planning, inventory optimization, and supply chain decisions.

Over time, this shift helps manufacturers stay responsive, reduce waste, and plan with far more confidence, even as demand patterns continue to change.

At X-Byte Analytics, we see this journey up close. Our work in manufacturing data analytics consulting and supply chain data analytics consulting is focused on helping manufacturers make sense of their data in a practical, business-first way.

The goal isn’t complexity, it’s clarity. When analytics supports everyday decisions quietly and consistently, demand forecasting becomes a strength that manufacturers can rely on as they grow and adapt.